Europe has announced that combustion engines will be allowed after 2035 only if they are powered by synthetic fuels. However, the question arises as to how the EU plans to ensure that this requirement is met.

Could the era of small mechanics performing routine maintenance such as oil changes and filter replacements be coming to an end? Perhaps not. While Europe has indeed voted to phase out cars that emit CO2 by 2035 (assuming there are no major changes to the plan), it is not necessarily the end of the road for combustion engines. The nuance is important: it is not the engines themselves that will be banned, but rather vehicles that are not carbon-neutral. At the urging of several countries including Germany, Poland, Bulgaria, and Italy, the EU has modified the legislation to allow for combustion engines running on synthetic fuels to remain in the market.

The principle of producing synthetic fuels involves capturing CO2 from the air, which is then released into the atmosphere during combustion, making the process carbon neutral. However, there are still other pollutants (such as carbon monoxide, ozone, and unburned matter) released during combustion that are not regulated by the EU’s final text. Although combustion engines running on synthetic fuels will be allowed after 2035, it is unclear how the EU plans to ensure that these vehicles are not fueled with traditional gasoline. It may take several years for the technical regulations to be established due to the recent implementation of the European law.

Start your combustion engine vehicle only if…

At present, it remains unclear how Europe plans to ensure that combustion engine vehicles sold after 2035 run only on synthetic fuels and not on fossil fuels, which are likely to remain prevalent. It would be impractical to monitor each driver individually. The approach may instead be “passive,” relying on a system that detects whether the vehicle is being filled with synthetic fuel. Synthetic fuels are chemically distinct from petroleum-based fuels because they are derived from the conversion of methanol, meaning they lack the benzene and aromatics present in unleaded fuel.

It is conceivable to develop a device capable of detecting the chemical composition of the fuel being injected into the combustion chambers in real-time. This way, it would be easy to identify any characteristic markers of traditional gasoline, and the engine would automatically switch to a degraded mode. Additionally, oil companies could potentially introduce unique markers into unleaded fuel to make it easier to distinguish from synthetic fuels.

Could a solution developed in France be the answer?

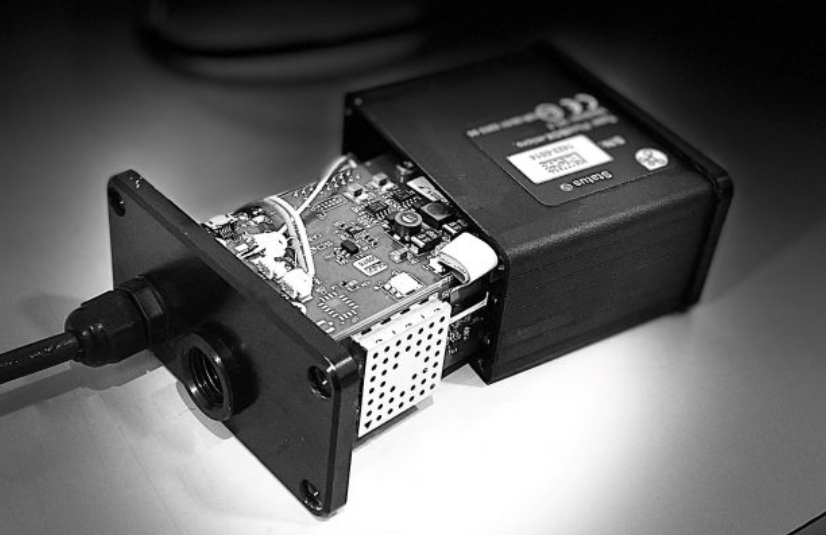

Coincidentally, history may be playing in favor of a possible solution. In issue 768, published in 2010, we covered the story of an ex-BP executive involved in the development of a company called SP3H, based in Aix, France. The company specializes in chemical analysis and creates devices that use an infrared scanner for real-time analysis of the molecular structure of various organic fluids. While its primary clients are currently refiners and the heavy transport sector, there is potential for this technology to be used in cars.

In fact, we previously reported on this scenario in our articles. The SP3H sensor was tested as a prototype in gasoline-powered light vehicles. The aim is to provide real-time data on the fuel’s characteristics (such as volatility and ethanol content in E85) to the vehicle’s computer, which can adjust the fuel injection accordingly, including ignition timing and fuel mixture management. The ultimate goal is to achieve better combustion and more effective pollution control. It would not be a significant leap to see this near-infrared light sensor technology implemented in cars designed to run on synthetic fuels.

A cost-effective and compact solution

According to the CEO of S3PH, if the unit were to be industrialized, its cost could be reduced to a few tens of euros. The unit, which weighs only a few hundred grams, could be placed close to the engine and injection, taking up very little space – as compact as an E85 unit or even more so. We recently had the opportunity to interview the CEO of S3PH.

The SP3H sensor is already being used on fleets of trucks that run on HVO, a biofuel used in some European countries. Companies that use this fuel are entitled to exemptions in France, such as an additional tax depreciation of 40% to 60%, as long as the truck performs well on HVO. To prove this, some carriers have implemented the SP3H device. If the truck were to be filled with regular diesel, the sensor would detect the presence of fossil fuel and trigger the engine’s degraded mode.

One advantage of SP3H’s solutions is their adaptability not only to private vehicles but also to older vehicles equipped with injection and a computer. This means that retrofitting these sensors would allow older cars to continue running on synthetic fuels for a few more years. It’s a new form of retrofitting!

However, even if the EU decides to adopt these specifications, there are still some unanswered questions. For example, will there be a sufficient number of filling stations supplying synthetic fuel after 2035? Furthermore, how can we prevent individuals from easily bypassing the fuel sensor, similar to those who decatalyze their vehicle for performance purposes or “flash” the computer?

The energy cost of synthetic fuel is substantial

According to the ratio of synthetic fuels to electrical energy stored in a battery, 5 to 6 times more electricity is required to produce synthetic fuels and operate a thermal vehicle than to propel a battery electric vehicle of equivalent mass. Although Aramco has claimed that it can produce a liter of synthetic fuel at €1 by 2028/2030, it is uncertain whether the necessary renewable energy parks will be constructed in deserts and windy regions to produce sufficient electricity for synthetic fuels. Therefore, although synthetic fuel is a potential option for European road transport in the medium term, it is uncertain how it will be used in relation to electric batteries and hydrogen.